|

Cospak NZ |

|---|

At Cospak New Zealand, we are conscious of the impact that packaging can have on the environment. We have a long history of experimentation, development and real-world results in this area.

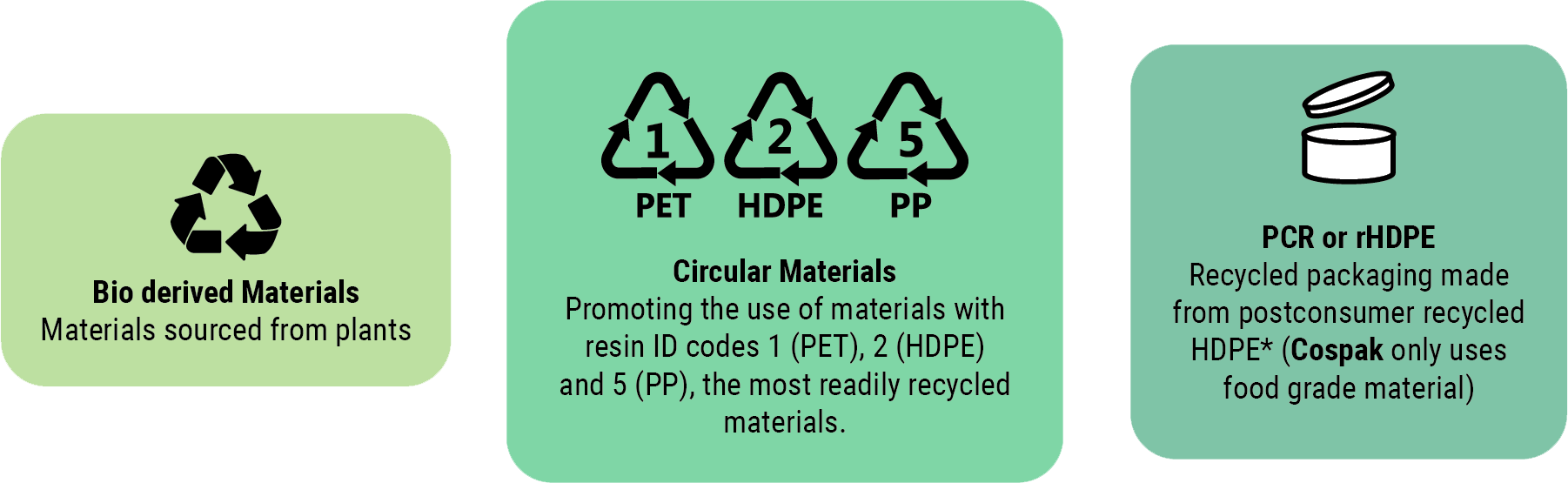

We support the global move towards circularity and the increasing demand for packaging materials that are kinder to the environment. We offer packaging made from bio-derived materials, recycled content materials, or simply using readily recyclable materials.

With our expansive knowledge we can help you find the right solution for your application.

A wide range of the plastic products we provide are made onsite in Auckland.

We are proud to offer a growing range of more sustainable alternatives to petroleum based, traditional virgin plastic.

Bio derived HDPE is made from ethanol extracted from sugarcane.

Sugarcane sequesters carbon from the atmosphere as it grows and is a renewable resource.

Bio-derived HDPE can be used in a wide range of packaging applications, including bottles and food containers.

Bio derived HDPE is chemically identical to traditional petroleum based HDPE and is readily recycled in the same recycling stream.

Post consumer recycled HDPE (rHDPE) is made from recycled milk bottles.

By increasing the use of recycled materials, demand for recycled resins is increased and less plastic goes to landfill.

Importantly for the majority of the products we supply, we can offer an rHDPE resin that is food contact approved.

At the most basic level, simply choosing 'circular' materials can enable recycling, thus minimizing the impact on the environment.

Material such as identification codes 1 (PET), 2 (HDPE), or 5 (PP) are considered to be the easiest to recycle, due to the volume of these plastics already in use.

Natural materials without colourant are of greater value to recyclers, and where colour is used, colourants like carbonless black can be chosen to increase recyclability.

The vast majority of excess material generated during our plastic product manufacturing processes (sometimes referred to as Post Industrial Waste) is close loop recycled onsite. Any resin that is not suitable for this purpose is collected by our recycling industry partners.

As widely publicised, plastics, when not properly handled post use, can be problematic in the environment.

Cospak New Zealand is Operation Clean Sweep certified, with the goal of achieving zero pellet, flake and powder loss within production and our operations.

Plastic does have sustainability benefits in certain areas over the likes of glass, due to the lower energy requirements in production.

As well as being an incredibly practical design, our range of dividers are made from 100% recycled content.

Cartons being of plant based origin coming form a renewable resource

Though glass packaging requires high energy inputs and tends to be heavier than alternatives - it has unique properties and a long history of use and recycling infrastructure.

Glass has excellent barrier properties, ensuring that oxygen and moisture sensitive products last longer, reducing wastage from spoiling. It is made from abundant natural resources like sand, limestone, and soda ash, and can be recycled indefinitely without any loss in quality.

These characteristics make glass an attractive choice for eco-conscious consumers and businesses looking to reduce their environmental impact.

Cospak provide aluminium drinking cans to growing number of home grown beverage providers. Aluminum is a highly recyclable material that can be recycled repeatedly without any loss in quality. This property makes aluminum cans a valuable resource in the circular economy.

When aluminum cans are recycled, they can be melted down and transformed into new cans with just a fraction of the energy required to produce cans from virgin materials.

Cospak is constantly monitoring it's policies, procedures and operations to ensure they align with the Ministry for the Environment.

The Ministry's latest sustainability strategies* includes short and long term goals, the most relevant to Cospak being the Government Waste Work Programme**.

Cospak complies with all three tranches of the phase-out of hard-to-recycle plastics, including PVC and expanded polystyrene packaging products.

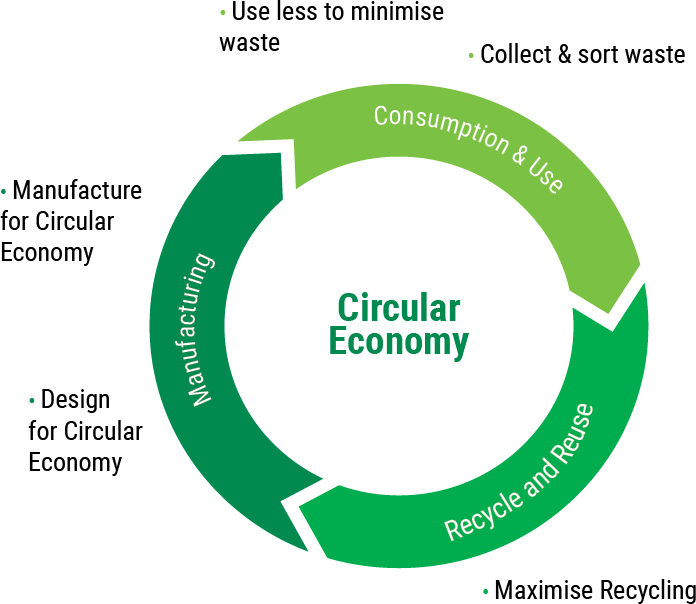

We support New Zealand's move towards a low-waste, circular economy, reducing the amount of materials used, reusing where possible and recycling materials after use.

In addition, Cospak supports the Ministry's strategy by implementing initiatives such as efficient lighting systems and transitioning our equipment to more efficient electric machines for production. These initiatives will help to reduce our emissions.

* https://environment.govt.nz/

** https://environment.govt.nz/

Our commitment to sustainability motivates us to seek opportunities for continuous improvement.

We continue to maintain our ISO 9001:2015 accreditation and became Operation Clean Sweep certified in 2020 (with the goal of achieving zero pellet, flake and powder loss).